|

|

|

KRM

2512 Soladrill

The KRM

1706 Soladrill has been designed to become an integral part

of your cultivation implement to give a compact one-pass seedbed

preparation and sowing unit. Extra close coupling saves weight

and reduces overhang allowing the use of a lighter tractor

for reduced compaction.

|

|

|

|

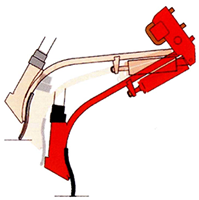

KRM

Elite Coulter

|

|

Elite

tine coulters are mounted in three rows on equal length arms.

Pressure is supplied by a heavy duty spring positioned at

a shallow angle below the tine. This geometry ensures that

for each movement of the tip the corresponding deflection

of the spring is small resulting in more even pressure and

therefore depth. This system works equally well when shallow

drilling (rape) or deep drilling (peas) as well as in varying

soil conditions.

|

|

|

|

| |

|

|

Standard

Features

|

|

|

|

The

solatronic control box monitors all key areas of sowing including;

forward speed, area sown, fan speed, hopper level and tramline management.

|

|

| When

on a tramline bout the tramline valves save seed back to the tank,

preventing over sowing and ensuring a clean start to each tramline.

As standard two shutoffs are used per wheeling, three can be specified

to accommodate large/flotation tyres. |

|

|

|

Heavy

duty, power harrow mounted markers leave an easily visible mark. The

angle of the large diameter marker disc's can be adjusted to ensure

a clear mark is left in difficult seed beds. |

| The

central metering unit offers precise control of sowing rate from 2

to 400kg/ha and ensures even seed spacing. The seed is metered into

a high speed air stream then distributed to the individual coulters.

This unit offers easy calibration, simple setting and fast hopper

emptying. |

|

| |

|

|

The

offset metering unit makes application rate adjustment and calibration

easy. Removing a thumb screw allows the venturi to drop away providing

unimpeded access to collect the metered seed. |

|

| |

|

|

Three

rows of elite tine coulters with a 40cm stagger and 12.5cm row spacing

ensure even seed depth is maintained. Adjustment through a parallel

linkage ensures pressure on all coulters is identical for constant

depth. |

|

Two

rows of staggered following harrow tines leave a level seedbed.

The maximum working depth of the tines can be adjusted as can tine

pressure and angle.

|

|

|

|

|

|

3.5m 2512 Power

Harrow Mounted

Pictured here

on our 180hp Maxim Power Harrow this 2512 drill has been specified

to include PE markers. Close coupling of the drill to the harrow

keeps weight close to the tractor for reduced lift requirement.

|

| |

|

|

|

4m 2512 Power

Harrow Mounted

Pictured here

on our 250hp Magnum Power Harrow. Close coupling of the drill to

the harrow keeps weight close to the tractor for reduced lift requirement.

|

| |

|

| |